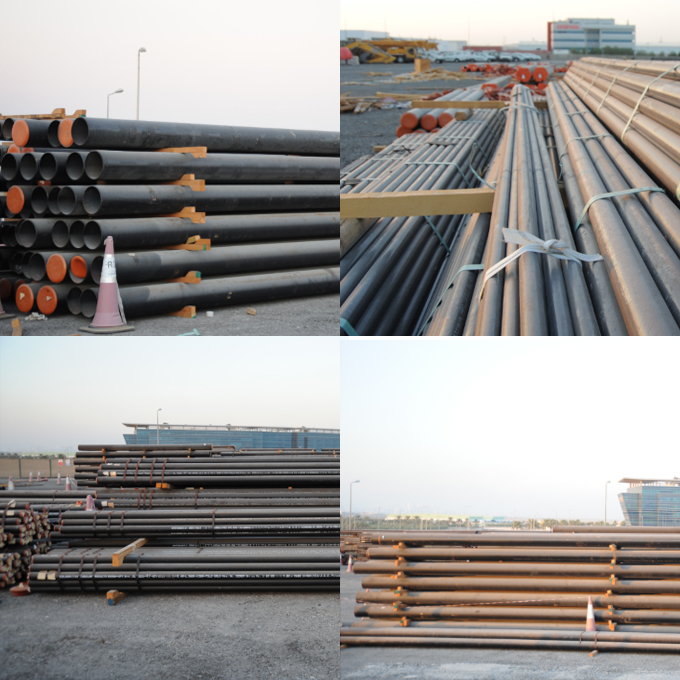

Comprehensive Piping Products

JSS Pipes provides a variety of welded pipes for different industries. We offer quality welded pipe products. Our product catalogue helps you find the right pipes for individual needs.

25+ Years of Industry Experience

JSS Pipes has over 25 years of experience as one of the spiral welded pipe suppliers. We understand what customers need and deliver solutions that meet industry standards.

Project Supply Division

Our Project Supply Division is ready to help with large projects by providing bulk orders. We supply pipes for many uses and ensure timely delivery to avoid any last-minute hustle.