Quality You Can Count On:

We provide forged flanges that meet top industry standards for strength, durability, and performance. Our advanced manufacturing techniques set us apart as a dependable forged flanges manufacturer in the UAE.

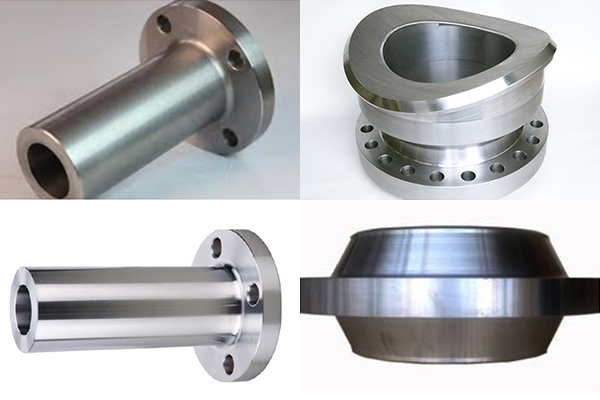

Multiple Forged Flange Options:

We offer a variety of forged flanges, from basic to highly specialized options, to meet your needs.

On-Time Delivery:

We understand how important it is to maintain the timeline of your projects. Our streamlined supply chain guarantees that you will receive your forged flanges punctually, without exception.