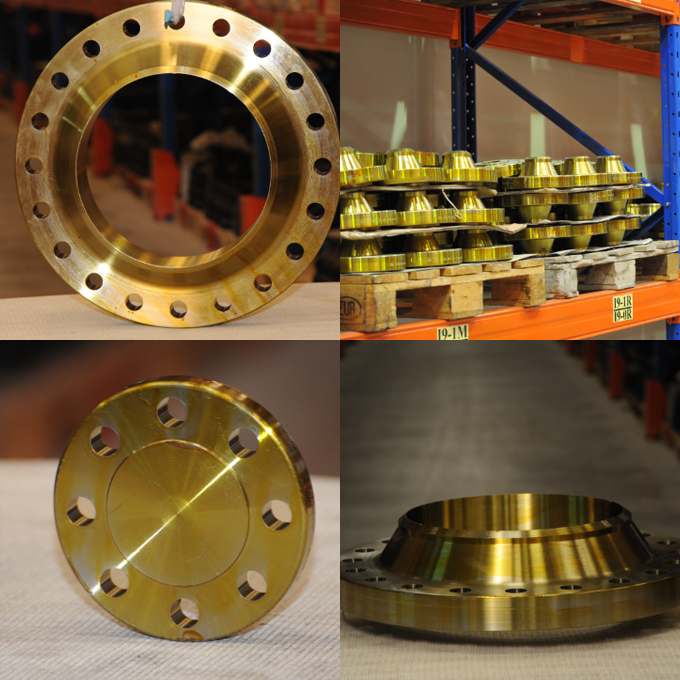

Slip-On Flanges

These flanges work well in low-pressure situations. They are easy to install and align, making them a flexible choice.

Weld Neck Flanges

These flanges are built for high-pressure systems. They offer firm support and resistance, making them durable in harsh conditions.

Blind Flanges

Blind flanges are great for sealing pipes. They also help with maintenance and repairs and are reliable and easy to use.