Cast Steel Gate, Globe And Check Valves

Cast Steel Gate, Globe And Check Valves

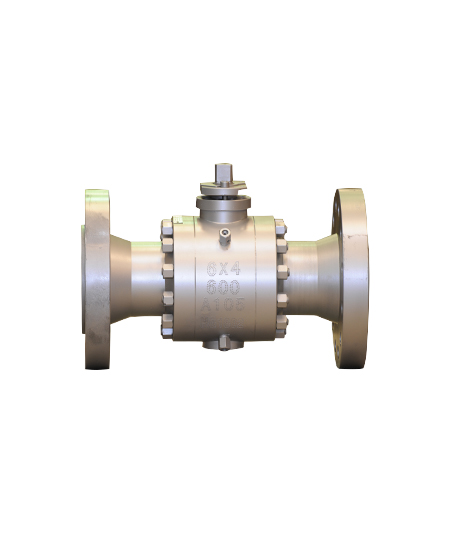

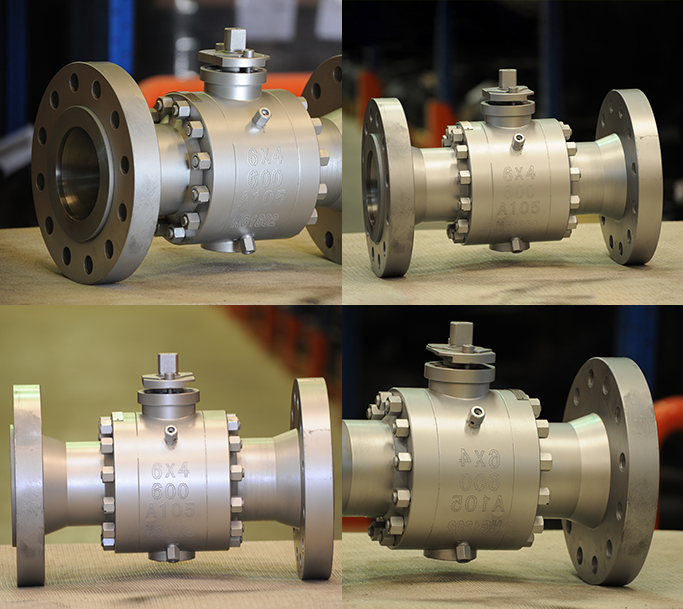

Specification

Design: API600, BS1414, BS1873, BS1868

Sizes: 1/2″ to 24″

Pressure Ratings: Class 150, 300, 600, 800, 900, 1500, PN16, PN25 and PN40

Connections: Flanged

Materials: Carbon Steel, LTCS, Stainless Steel

Cast Steel Gate, Globe, and Check Valves: Durable Solutions for High-Pressure Applications

Types of Cast Steel Valves Offered

Gate Valves: Reliable On-Off Control

Gate valves are primarily used for on-off control, providing a straight flow path with minimal pressure drop.

Key Features:

- Wedge or parallel disc design for tight sealing

- Smooth, unobstructed flow when fully open

- Suitable for high-pressure and high-temperature environments

Applications:

- Oil and gas pipelines

- Water distribution networks

- Industrial processing plants

Advantages:

- Excellent sealing capability

- Highly durable and reliable

- Ideal for high-temperature and high-pressure applications

- Long service life with proper maintenance

Globe Valves: Precision Flow Control

Globe valves are built to control fluid flow accurately, making them perfect for applications requiring precise flow regulation.

Purpose & Functionality:

- Designed for precise flow regulation

- Provides effective sealing, reducing leakage risks

- Suitable for frequent operation adjustments

Flow Control & Efficiency:

- Enhanced shut-off capabilities

- Reduced turbulence and pressure loss

- Long service life with minimal maintenance

Check Valves: Preventing Backflow

Check valves are self-operating valves designed to prevent reverse flow, ensuring smooth and safe pipeline operations.

How They Work:

- Operate automatically without manual intervention.

- Close when downstream pressure exceeds upstream pressure.

Common Applications:

- Protects pumps and compressors from backflow

- Widely used in water treatment plants, oil refineries, and chemical processing facilities.

- Available in swing, lift, and ball-type designs

Specifications and Standards

Our cast steel valves meet global industry standards for safety and efficiency. We adhere to API600, BS1414 (Gate Valves), BS1873 (Globe Valves), and BS1868 (Check Valves) to ensure top-quality manufacturing. These standards define industrial valves’ performance, design, and durability criteria, ensuring they operate under high-pressure conditions without failure. Our valves come in sizes from 1/2″ to 24″, meeting a wide range of industrial requirements. With pressure ratings spanning Class 150, 300, 600, 800, 900, 1500, and PN16 to PN40, they are built to withstand demanding environments while ensuring optimal flow control and operational safety.

Material Options

- Carbon Steel: High strength and durability for general industrial use.

- Low-Temperature Carbon Steel (LTCS): Ideal for extreme cold conditions.

- Stainless Steel: This material is best suited for stainless steel valves in the oil industry, as it provides corrosion resistance and superior longevity.

Connection Types

Industries and Applications

Our cast steel valves are designed for a wide range of industries, ensuring efficiency and safety:

Oil & Gas

- Stainless steel valves for the oil industry are essential for handling high-pressure oil and gas transportation.

- Ensures leak-proof operation in offshore and onshore facilities, enhancing safety, efficiency, and environmental protection.

Power Generation

- Used in steam and cooling systems to regulate fluid flow effectively.

- Handles high temperatures and pressures in thermal power plants, ensuring reliable performance, durability, and operational safety.

Water Treatment

- Controls water flow and pressure in filtration and distribution systems, ensuring efficient operation and optimal performance.

- It prevents backflow contamination in pipelines and maintains water quality and system integrity.

Petrochemicals

- Handles aggressive chemicals and extreme process temperatures, providing reliable performance and corrosion resistance.

- Ensures safe flow control in chemical processing plants, enhancing operational efficiency and regulatory compliance.

Industrial Manufacturing

- Used in heavy-duty machinery and production lines, ensuring durability and high-performance efficiency.

- Guarantees precision fluid handling for smooth operations, minimizing downtime and optimizing productivity.

Why Choose Our Cast Steel Valves?

Stock Availability & Custom Orders

Contact Us for Inquiries & Orders

Looking for durable and efficient stainless steel valves for the oil industry? Contact J.S.S. Pipes & Fittings Trading L.L.C for expert guidance, competitive pricing, and hassle-free procurement. Whether you need standard valves from our stock or custom-engineered solutions, we’re here to assist with all your requirements.