Understanding the Manufacturing Process of Welded Pipes

Welded pipes are crucial in various industries, including construction, oil and gas, water transportation, and manufacturing. These pipes are made by shaping and fusing metal sheets or strips, providing a practical and budget-friendly alternative to seamless pipes. Their versatility, availability in different sizes, and suitability for high-pressure applications make them popular. Understanding the manufacturing process of welded pipes is essential to appreciate their reliability, strength, and efficiency. This guide explores the step-by-step process, from raw material selection to final inspection and packaging, ensuring high-quality pipes reach the end user.

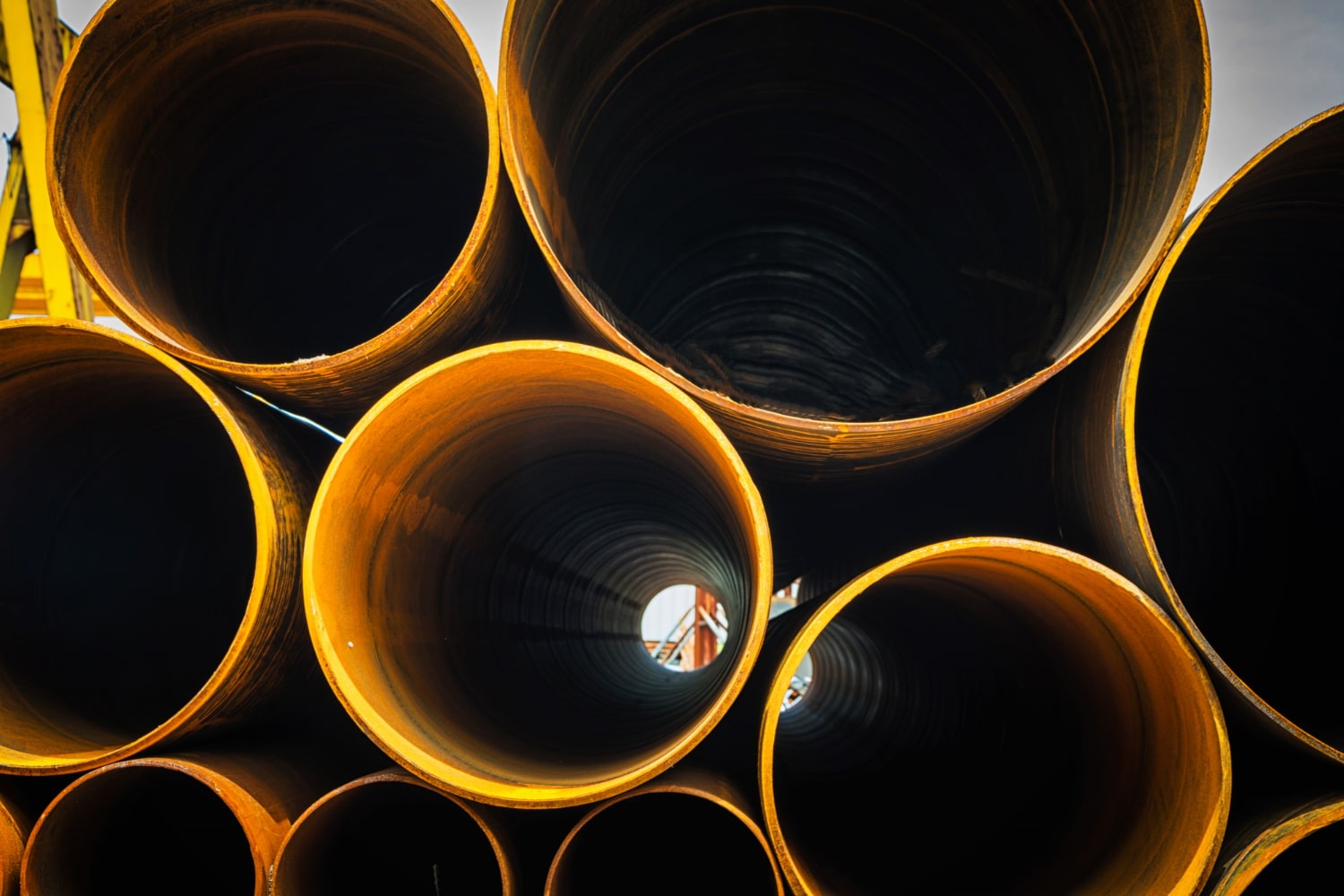

Raw Material Selection and Preparation

The foundation of high-quality welded pipes starts with selecting the right raw materials. Manufacturers choose carbon, stainless, or alloy steel based on the intended application and performance requirements.

Steel coils or sheets undergo a rigorous inspection to detect defects such as cracks, impurities, or inconsistencies in composition.

The material is thoroughly cleaned and treated to remove oxidation, rust, and surface contaminants, ensuring improved durability.

Precision cutting techniques are applied to achieve uniform width, contributing to consistent pipe dimensions and optimal weld integrity.

Forming the Pipe Shape

Once the raw material is prepared, it undergoes shaping to form the desired pipe structure. Metal sheets or strips are progressively shaped into a cylinder with the help of precision rollers or modern forming mills. This controlled process ensures:

Proper alignment of edges for seamless and strong welding.

Minimal material wastage, improving cost efficiency and sustainability.

Consistent wall thickness for enhanced durability, strength, and pressure resistance.

A smooth and uniform surface finish reduces the need for additional processing.

Welding Techniques Used in Manufacturing

Different welding techniques are used to join the edges of welded pipes, depending on their application, size, and material. The primary welding methods include:

Electric Resistance Welding (ERW)

This technique passes high-frequency electric current through the metal edges, generating heat to fuse them. ERW is commonly used for:

Producing pipes with a uniform thickness.

Manufacturing medium- and high-pressure pipes for oil, gas, and water applications.

Ensuring smooth, defect-free welds with minimal additional material.

Submerged Arc Welding (SAW)

SAW uses a continuous arc beneath a flux blanket to create deep and strong welds. It is ideal for large-diameter pipes used in:

Structural applications.

Offshore and onshore pipeline systems.

Heavy-duty industrial uses require high strength.

High-Frequency Welding (HFW)

HFW is a variation of ERW, using a high-frequency current to generate localized heat. This process offers:

Precision in welding thin-walled pipes.

High-speed production with minimal distortion.

Cost-effective manufacturing for mass production.

Heat Treatment and Stress Relief Techniques

After welding, welded pipes undergo a precise heat treatment process to relieve internal stresses caused by welding and forming. This controlled heating and cooling process enhances the following:

Mechanical strength, improving load-bearing capacity and performance.

Resistance to cracking, deformation, and structural weaknesses over time.

Overall durability, ensuring pipes meet strict industrial standards and operational demands.

Corrosion resistance and metallurgical stability extend the lifespan of the pipes in various applications.

Surface Finishing and Coating

Pipes undergo protective coatings and surface treatments to improve performance, longevity, and resistance to harsh environments. These processes enhance durability and ensure suitability for various applications.

Galvanization: This adds a protective zinc layer to prevent corrosion, especially in outdoor or moisture-prone environments.

Epoxy Coating: Forms a strong barrier against environmental exposure, chemicals, and abrasion, extending the pipe’s lifespan.

Pickling and Passivation: Removes surface impurities, rust, and scale while enhancing corrosion resistance and maintaining material integrity.

Polyethylene or Bitumen Coating: Provides extra protection for underground or submerged pipelines, reducing wear and external damage.

Quality Control and Testing Procedures

Quality assurance is vital in welded pipe manufacturing, guaranteeing durability, safety, and adherence to international standards. Multiple rigorous tests are conducted to verify reliability and performance:

Non-Destructive Testing (NDT): NDT utilizes ultrasonic, radiographic, or eddy current testing to detect internal defects, cracks, or inconsistencies without damaging the pipe.

Hydrostatic Testing: Fills pipes with pressurized water to check for leaks, structural weaknesses, and pressure-handling capabilities, ensuring operational safety.

Dimensional Inspection: Confirms precise diameter, wall thickness, and length, guaranteeing uniformity and adherence to project specifications.

Visual and Surface Inspection: Identifies surface imperfections, welding flaws, and coating defects to maintain aesthetic and functional quality.

Mechanical Testing: Evaluates tensile strength, hardness, and impact resistance to verify the pipe’s ability to withstand stress and environmental conditions.

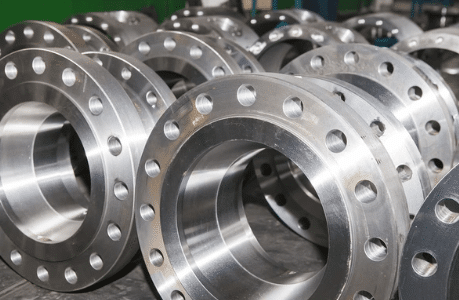

Final Inspection and Packaging

Welded pipes undergo a thorough final inspection before dispatch to guarantee they meet the highest quality and industry requirements. A reputable welded pipe supplier conducts thorough evaluations to verify the following:

The surface finish and weld integrity ensure smooth surfaces and defect-free welds for optimal performance.

Dimensional accuracy and thickness consistency, confirming compliance with specifications for safe and efficient application.

Proper marking for identification, including batch numbers, material grades, and manufacturing details for easy traceability.

Secure packaging to prevent damage, using protective wraps, end caps, and bundling to maintain quality during storage and transportation.

Applications of Welded Pipes in Various Industries

Welded pipes play a crucial role across diverse industries, offering strength, reliability, and versatility for numerous applications. They are indispensable for:

Oil and Gas: Used in pipelines, they ensure the smooth and secure transportation of crude oil, natural gas, and refined petroleum products.

Construction: Essential for structural frameworks, water distribution systems, scaffolding, and underground drainage networks, providing durability and stability.

Automotive Industry: Integral in exhaust systems, chassis components, fuel lines, and hydraulic systems, enhancing vehicle performance and longevity.

Mechanical Engineering: Widely used in heat exchangers, boilers, pressure vessels, and hydraulic piping systems, ensuring high-temperature and high-pressure resistance.

Agriculture and Irrigation: Supports irrigation networks, greenhouse structures, and water supply systems, contributing to efficient farming operations.

Conclusion

Manufacturing welded pipes involves multiple meticulous steps, from raw material selection to final inspection. Various welding techniques, heat treatment, and rigorous quality checks ensure durability and strength. Whether used in oil pipelines, construction, or industrial applications, these pipes offer an efficient and cost-effective solution. Choosing a reliable welded pipe supplier guarantees high-quality products tailored to industrial needs.

FAQs

What are the main types of welding techniques used in pipe manufacturing?

The key welding methods are Electric Resistance Welding (ERW), Submerged Arc Welding (SAW), and High-Frequency Welding (HFW). Each technique varies in application, pipe size, and production efficiency, ensuring suitability for different industries.

How does Electric Resistance Welding (ERW) work?

ERW applies a high-frequency electric current to the pipe edges, generating heat that fuses them. This technique ensures smooth, uniform welds, making it ideal for oil, gas, and water pipelines requiring high strength and consistency.

What is Submerged Arc Welding (SAW), and where is it used?

SAW creates deep, strong welds under a protective flux layer, minimizing contamination. It is used for large-diameter pipes in offshore and onshore pipeline systems, heavy-duty industrial applications, and structural projects needing high-strength materials.

Why is heat treatment necessary in welded pipe manufacturing?

Heat treatment removes residual stress from welding, improves mechanical properties, and enhances crack resistance. It ensures the pipes can withstand extreme conditions and meet safety standards for various industrial applications.

What quality control tests are conducted on welded pipes?

Quality tests include non-destructive testing (NDT) to detect internal defects, hydrostatic testing to check for leaks, and dimensional inspections to ensure accurate pipe specifications, reliability, and compliance with industrial standards.