Top Applications of Bothwell Fittings in Oil & Gas Industries

When quality and reliability are essential in the oil and gas industry, businesses look to bothwell fittings suppliers in the UAE for parts that will ensure strength, durability, and leak-proof performance. In oil and gas operations where failure is not an option, for example, Bothwell fittings are renowned for their exceptional reliability in numerous high-pressure, high-temperature environments. From upstream drilling to downstem processing, Bothwell fittings in critical infrastructure enable superior performance.

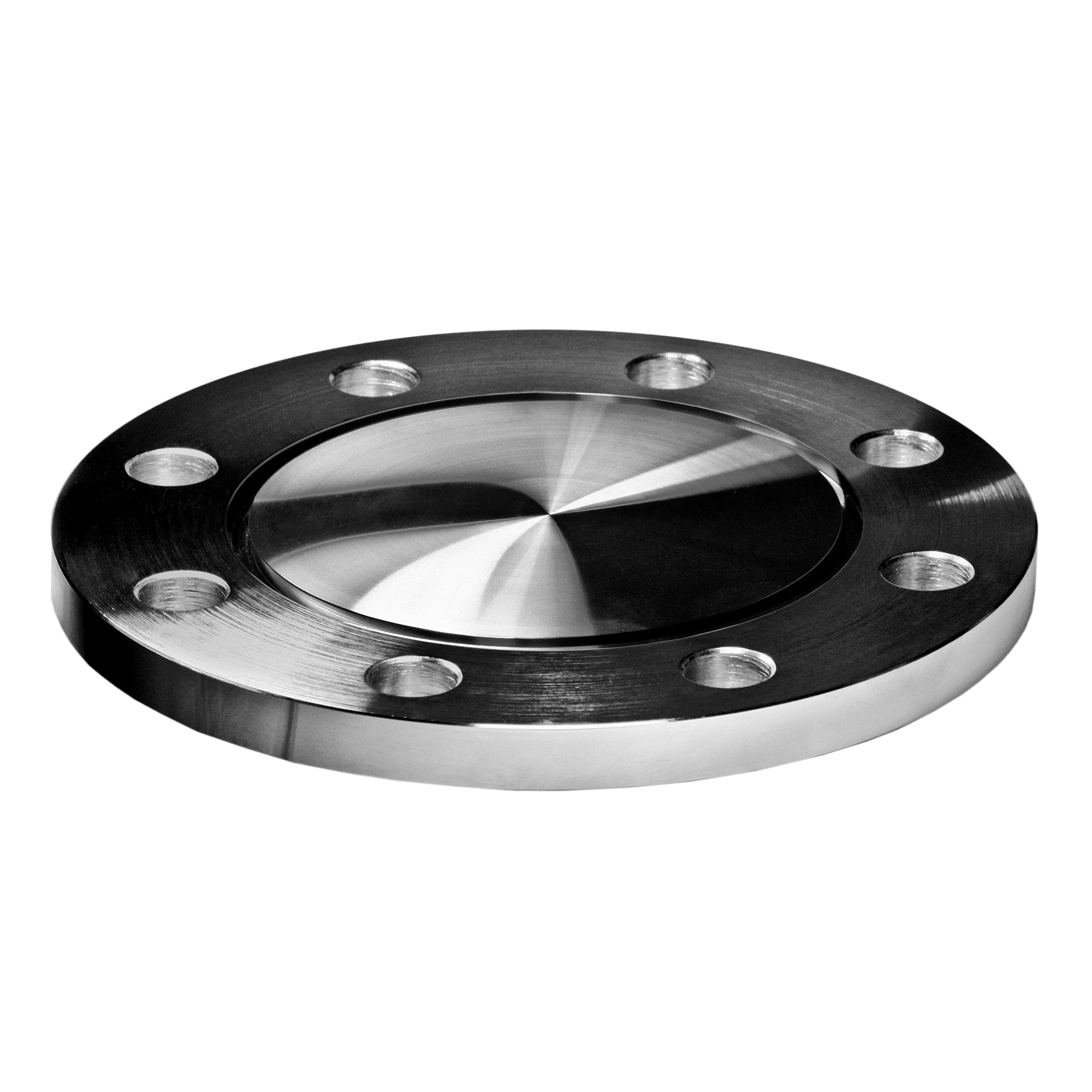

What Are Bothwell Fittings?

Bothwell fittings are heavy-duty fittings for securely connecting pipes in challenging industrial environments. They can be elbows, tees, reducers, or caps designed, made from carbon steel, stainless steel, and higher grade alloys; they stand out for one major reason: precision, strength, and performance under conditions that will compromise other parts of a hydraulic assembly, like extreme heat, pressure, and/or exposure to corrosive chemicals.

Advantages of Using Bothwell Fittings in Oil & Gas

People in the field choose Bothwell fittings for a reason—they work when it matters most. Here’s what makes them so reliable:

- Meets International Regulations: Bothwell fittings are compliant with ASME and ASTM standards, which means they meet the codes of quality and safety required by world standards.

- Tough in Harsh Environments: Bothwell fittings are durable enough to withstand the type of corrosion and stresses expected in offshore use.

- Leak-Proof Fit: Especially when installed by experienced butt weld fittings suppliers, the seamless joints help prevent leaks that can halt entire operations.

- Versatile for Complex Setups: Every oil and gas activity is unique, and accordingly, Bothwell fittings are available in various sizes and shapes for custom pipelines.

They’re not just parts—they’re peace of mind.

Top Applications in Oil & Gas Industries

You’ll find Bothwell fittings just about everywhere across the oil and gas lifecycle. Let’s break down a few key areas:

Pipeline Networks

When crude oil or natural gas needs to move across long distances, Bothwell elbows and reducers handle the pressure—literally. They keep things flowing, safely and efficiently.

Oil Refineries

High heat, high flow, nonstop operation—refineries demand a lot. Bothwell fittings help manage pressure and flow in distillation units, storage tanks, and heat exchangers.

Offshore Platforms

Salt, humidity, storms—offshore conditions are brutal. That’s why corrosion-resistant materials from trusted Bothwell fittings suppliers in the UAE are the go-to choice for marine environments.

Drilling Operations

In deep-sea or desert rigs, where safety is critical, Bothwell caps and tees help direct mud flow and manage pressure during drilling.

Gas Treatment Plants

Separating and compressing gas isn’t only technical, it’s also delicate. High-performance fittings reduce risk and help keep operations running smoothly.

How to Choose the Right Bothwell Fittings?

Choosing the right fittings is a little more complicated than simply choosing a size. A few things to consider are:

- Media Compatibility: Ensure you select compatible fittings with your media; i.e., acidic, Sour Gas, high-temperature elements, etc.

- Pressure Rating: Ensure the fittings are rated for the pressure of your system.

- Connection Type: When used with factory test-welded joints, butt weld fittings are the best option for achieving perfect, no-gap joints.

- Benchmark Standards: Verify if the fittings are certified to an applicable international standard (e.g., ASME B16.9 or ASTM A234).

- Scope of Work: Verify if standard sizes will suffice or if custom designs are required for the more complex parts of the piping procedure.

By working with bothwell fittings suppliers in the UAE, you will have help deciding on fittings to meet acceptable safety and performance standards and remain within a competitive price range.

Future Outlook: What’s Next for Bothwell Fittings?

As oil and gas companies rely on more demanding locations and harsher conditions, fittings like Bothwell are enhancing their ability to perform the task. Innovation is accelerating in fittings, from hydrogen-ready components to high-alloy fittings for acidic gas service. There will only be a larger need for proven fitting durability, especially in regards to reliable suppliers of butt weld fittings.

Conclusion

A small unsealed joint or a brittle weld in the oil and gas industry could lead to disaster. For this reason, bothwell fittings suppliers in the UAE and other oil and gas fittings manufacturers are chosen based on their dependability of fittings. Bothwell suppliers are trusted as their products deliver under pressure, remain dependable throughout chemical corrosion, and promote longer and safer operation of systems. They continue to secure their positions in pipeline construction and complex refineries with critical connection products.

FAQs

What standards do Bothwell fittings comply with?

They’re manufactured to meet ASME, ASTM, and ANSI standards, ensuring safety, reliability, and global compatibility.

Are Bothwell fittings suitable for sour service conditions?

Yes, many Bothwell fittings are made from corrosion-resistant materials specifically engineered for sour gas and offshore environments.

How do Bothwell fittings improve safety in pipelines?

They create strong, sealed connections that reduce the risk of leaks, bursts, or mechanical failure, especially under pressure.

Can Bothwell fittings be customized for special projects?

Absolutely. Reputable butt weld fittings suppliers can provide customized solutions based on size, pressure rating, and material requirements.

Where can I source genuine Bothwell fittings in the UAE?

Look for authorized Bothwell fittings suppliers in the UAE who offer full certification, technical support, and a wide inventory of fittings.